Our Battery Recycling Program is based on a cradle-to-cradle approach, ensuring that what goes into our batteries is safe and efficient from manufacturing to reuse and end-of-life recycling. We aim to support our customers in responsibly handling batteries, reusing key parts, refurbishing batteries, and donating recouped storage systems to programs around the world for people who need them.

Why is battery recovery important to us?

Batteries, particularly those used in energy storage systems, contain salvageable materials. These materials can be recovered through reuse, refurbishment, and, as a last resort, recycling. By recycling batteries, we can play a pivotal role in conserving these precious natural resources.

Battery recycling is essential for safeguarding the environment. Improper battery disposal can lead to chemical leaching into soil and water, posing significant risks to ecosystems and human health.

By recovering materials from every battery, Briggs & Stratton Energy Solutions minimizes waste and prevents these harmful chemicals from entering the environment. Preserving resources helps mitigate pollution by reducing the need for new raw materials, thus lowering the environmental footprint associated with battery production. As a company with over 118 years of experience, we know the value of making material plans for the long-term and preserving our resources.

How do we apply cradle-to-cradle practices to battery storage?

Battery recycling aligns with our broader sustainability goals by promoting a circular economy. Briggs & Stratton Energy Solutions’ LFP batteries are manufactured with materials that are 90% reusable or recyclable. When we think about the lifecycle of batteries, it's not just about using them and throwing them away. If we start planning for their future from the moment they're made, we can make sure they have many lives ahead. Instead of discarding them after their first use, we can refurbish, repurpose, and eventually recycle them. This gives batteries a longer life and makes the most of our resources. By adopting this cradle-to-cradle approach, we cut down on the need for new materials, reduce energy use, and decrease greenhouse gas emissions. It's a smarter way to handle resources that are, after all, finite.

Making an impact through refurbishment and donation

Refurbished batteries that meet Briggs & Stratton Energy Solutions' rigorous standards are donated to non-profit organizations and underserved communities worldwide. Through partnerships with various organizations, we have had the honor of empowering schools, healthcare centers, and conservation efforts across the globe, making a tangible difference in people's lives through energy storage.

In Fiji, our partnership with the It's Time Foundation has transformed the educational experience for schools on remote islands. By implementing solar-powered systems that include our refurbished Briggs & Stratton SimpliPHI batteries, these schools have seen significant savings in energy costs. This has allowed them to redirect funds towards essential educational resources like school supplies and teacher salaries, thereby enhancing the learning environment for students.

When it’s time to recycle your LFP battery

Each battery is tested upon arrival to assess its remaining capacity and overall health. Using advanced diagnostic tools, our technicians measure key performance metrics to identify which batteries can be restored to full or near-full functionality. Our goal is to ensure that each battery can serve a purpose beyond its initial life. When it’s determined that a battery cannot be refurbished, it is dismantled for its parts, and the remaining battery is sent to our recycling partners to recover the final materials.

Environmental advantages of LFP batteries

Briggs & Stratton Energy Solutions is committed to sustainability, and our LFP batteries are at the heart of this commitment. What's great about these batteries is that they break down into non-toxic compounds, making their disposal safe and environmentally friendly. Their production process is also designed to minimize environmental impact, which shows how serious we are about our commitment to the planet.

LFP batteries provide notable environmental advantages when contrasted with other prevalent battery varieties like lithium cobalt oxide (LiCoO2). Their chemistry inherently prioritizes safety, boasting reduced risks of thermal runaway and the absence of toxic gas emissions during operation or damage. This inherent safety profile positions them as an optimal selection for various applications, from residential energy storage to critical backup systems.

Our support for recycling goes beyond our products. Briggs & Stratton has implemented a company-wide e-recycling program for employees. Cost-free and available at on-site locations, staff can bring their end-of-life electronics for recycling anytime they want. We encourage this practice and are thrilled to have this easy program, especially when e-waste recycling is sometimes hard to find or is only at certain times.

Briggs & Stratton Energy Solutions' Battery Recycling Program exemplifies its dedication to responsible environmental practices. By embracing cradle-to-cradle responsibility and prioritizing battery reuse and refurbishment, the company is not just reducing waste—it is leading the charge towards a more sustainable future, one battery at a time. Join Briggs & Stratton Energy Solutions in its mission to make a positive impact on the planet through responsible battery management.

What is the recycling process for LFP batteries?

Shredding and separation

The recycling process begins with shredding the entire battery. This method is cost-effective and mitigates fire risks associated with battery disposal. After shredding, mechanical components such as copper, aluminum, and plastics are separated.

Wet chemistry process

Following mechanical separation, a wet chemistry process is employed to separate valuable materials like nickel and lithium further. This process ensures that every recoverable material is salvaged in the most environmentally responsible way.

Recycling your battery

To recycle your battery, contact us. Depending on your location and battery type, we will facilitate communication with our core recyclers. We also provide specific instructions on preparing and shipping your battery to ensure safety and compliance throughout the process.

This comprehensive approach supports our environmental goals and assists our customers in contributing to more sustainable practices.

A step-by-step guide for customers

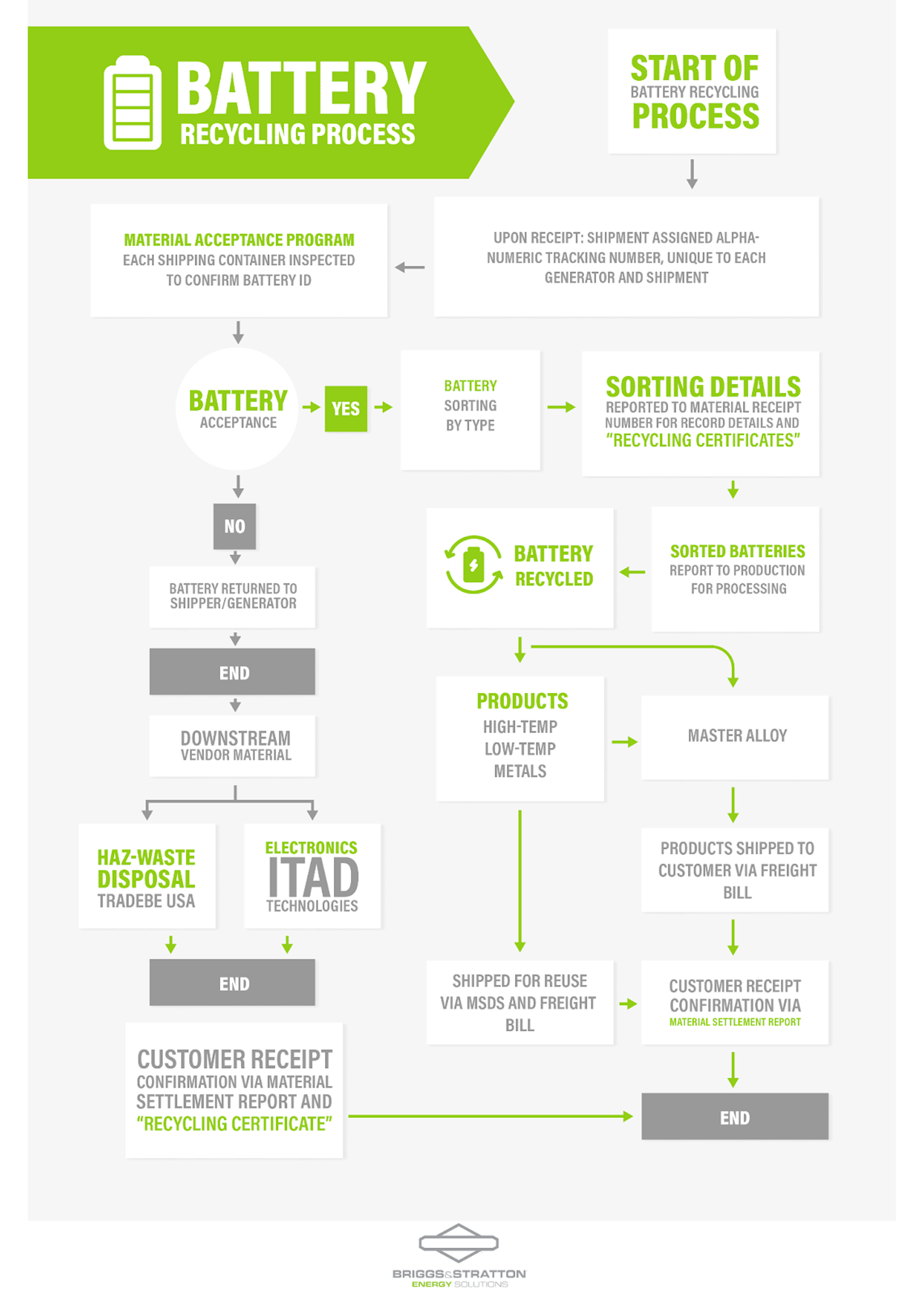

We make the process simple and handle batteries using the following steps.

Step 1

Identify your battery type. Ensuring eligibility for the recycling program is as easy as verifying that the battery in question is a Briggs & Stratton Energy Solutions SimpliPHI product.

Step 2

Recycling customers are encouraged to contact Briggs & Stratton Energy Solutions to initiate the recycling process. From arranging logistics to providing detailed packaging instructions, we ensure that the right steps are taken to facilitate safe and efficient shipping and recycling.

Step 3

Once the battery is securely packaged, customers are guided through the process of shipping it to the appropriate location for recycling. With clear instructions and our support, responsible disposal becomes a straightforward endeavor.

Contact us for more information about recycling your LFP battery.

Call: (805) 640-6700

Ready to experience true energy independence?

Request a consultation with a Briggs & Stratton dealer or installer near you by clicking the button below.