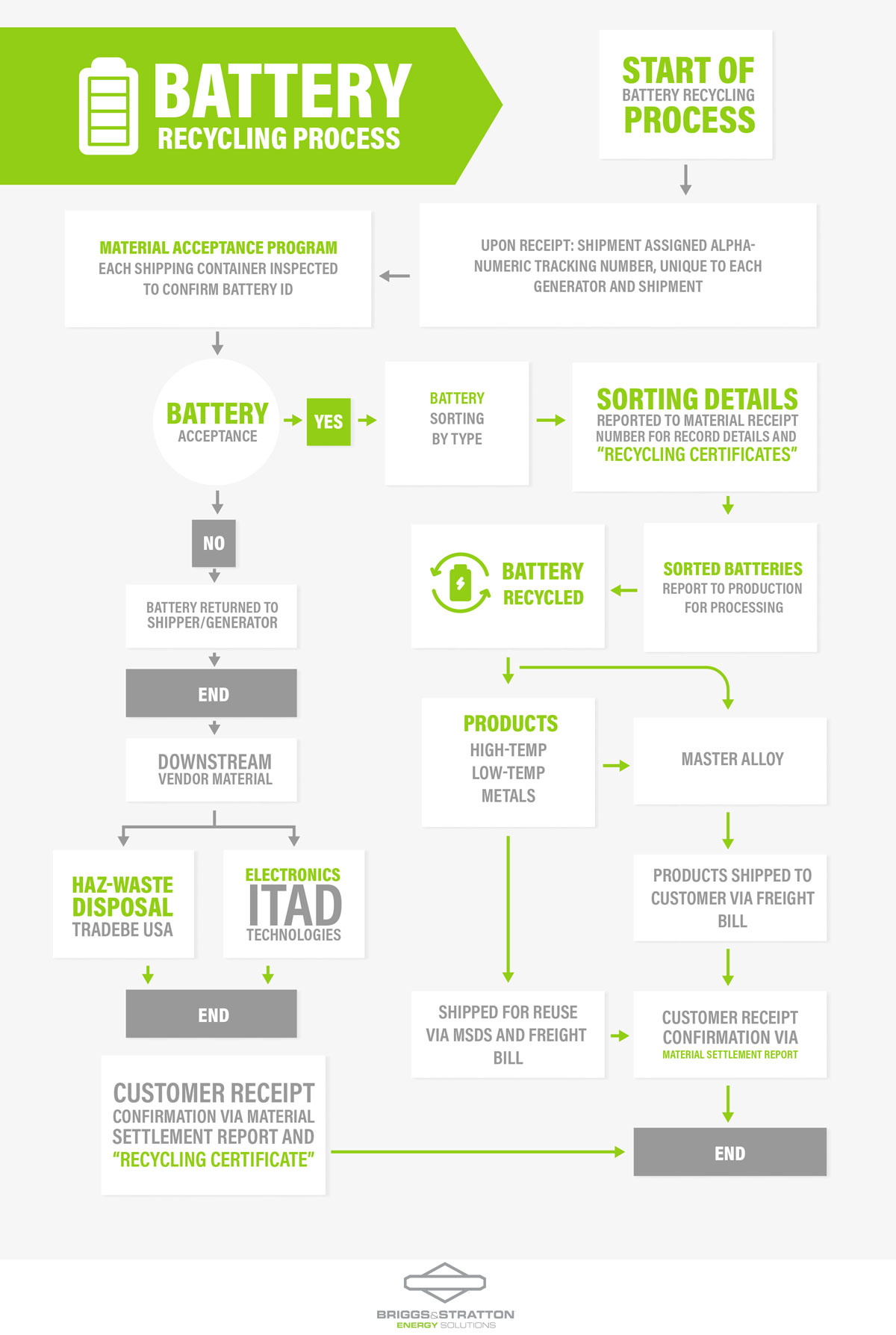

At Briggs & Stratton Energy Solutions, we recognize our role in executing excellence for the entire lifecycle of our products, from the time they are designed and manufactured to their usage and end-of-life. Our commitment extends beyond the quality of our products to encompass a comprehensive approach to responsible environmental practices. We are dedicated to reducing waste and ensuring our products return to our facilities for refurbishing or go to one of our recycling partners to recover the materials from every battery. We also support our customers and employees in doing the same. Learn more about our Battery Recycling Program process here.

Step-by-Step Guide for Customers

Step 1

Identify Your Battery Type

Ensure your battery is a Briggs & Stratton SimpliPHI product to confirm eligibility for our recycling program.

Step 2

Contact Us for Recycling

Contact Briggs & Stratton Energy Solutions to arrange logistics. We will set up the appropriate logistics necessary for you to safely package your battery, covering all terminals to prevent short-circuiting. You can also refer to our installation manual for detailed instructions on proper packaging that carries the UN3480 labeling.

Step 3

Prepare Your Battery for Recycling

Once your battery is ready, follow the instructions and materials provided to ship your battery to the appropriate location. We will provide you with the necessary information to initiate recycling your battery.

Why Is It Important to Recycle Battery Storage Systems?

- Battery recycling helps conserve natural resources as many battery components can be recovered, reused, or placed into refurbished batteries.

- Recycling prevents harmful battery chemicals from entering the environment, thus reducing pollution and safeguarding ecological health.

- We view battery material recovery as an essential component of product lifecycle management and a critical aspect of environmental stewardship.

Our Cradle-to-Cradle Approach to Batteries

Our approach to battery management is rooted in the principles of cradle-to-cradle responsibility. We ensure that every battery we produce is given multiple lives through refurbishing, reusing, and donating before it reaches the recycling phase. This extends the useful life of our batteries and maximizes the environmental benefits of our recycling program.

As an industry leader in energy solutions, we know the value of energy independence and the peace it brings. We're committed to the highest standards of sustainability and environmental protection. Battery storage systems are integral for energy stability, and when a battery reaches its end-of-life, we like to assume it could have another one, as a refurbished battery or as parts for a refurbished battery that can be donated to one of many important causes.

How the Battery Recycling Program Works

Battery Reuse and Refurbishment

Every battery shipped for recycling undergoes a detailed assessment to determine its suitability for refurbishment, reuse, or recycling.

Identification Process

Each battery we receive is first tested to evaluate its remaining capacity and overall condition. Our technicians use advanced diagnostic tools to precisely measure performance metrics and identify batteries that can be restored to full or near-full functionality. If the battery can’t be repaired, its parts are used to refurbish other batteries or sent to our partners for recycling.

Refurbishment and Certification

Batteries that pass our initial testing undergo a comprehensive refurbishment process. This includes replacing worn or damaged components and undergoing rigorous safety checks. Once a battery is refurbished, it is re-tested to ensure that it meets specific performance standards. Only batteries that meet these stringent criteria are certified for reuse and donation.

Donation and Partnership Programs

Refurbished batteries that are certified for reuse are most often donated to non-profit organizations and underserved communities, providing them with essential energy solutions. We have established partnerships with several organizations that help distribute our refurbished batteries where they are needed most. These partnerships extend the life of our batteries and contribute to energy equity by supporting communities with unreliable power access. Learn more in our stories of impact below.

Through these battery donation efforts, we aim to ensure that nothing goes to waste. Up to 90% of all battery components are recycled or repurposed. By prioritizing battery reuse and refurbishment, we maximize the lifecycle of our products and minimize our ecological footprint, one battery at a time.

Battery Refurbishment Stories of Impact

California’s Mobile Solar for High-Risk Communities Project

In collaboration with Empowered by Light and the Footprint Project, we have deployed mobile solar and battery trailers for California's firefighters and first responders. These units are crucial during wildfires and other emergencies, providing a dependable power source for charging vital communication and medical equipment.

Our designated recycling companies handle most of our battery parts and cells, supporting business and retail customers. This process ensures compliance with federal, state, municipal, EPA, and DOT regulations governing the recycling of waste batteries and select electronics.

By recycling LiFePo4 batteries, we actively reduce waste in our landfills, prevent harmful chemicals from contaminating our soil and water, and preserve our environment by decreasing the need for new raw materials.

Safe Decomposition and Recycling Technologies

Our designated recycling companies handle most of our battery parts and cells, supporting business and retail customers. This process ensures compliance with federal, state, municipal, EPA, and DOT regulations governing the recycling of waste batteries and select electronics.

By recycling LiFePo4 batteries, we actively reduce waste in our landfills, prevent harmful chemicals from contaminating our soil and water, and preserve our environment by decreasing the need for new raw materials.

Environmental Advantages of LFP Batteries

LFP batteries offer significant environmental benefits compared to other common battery types, such as lithium cobalt oxide (LiCoO2). The LFP chemistry is inherently safer, with a lower risk of thermal runaway and no release of toxic gases during operation or when damaged. This safety feature makes them an ideal choice for a wide range of applications, from residential energy storage to critical backup systems.

Safe Decomposition

One of the remarkable features of LFP batteries is their ability to safely decompose at the end of their lifecycle. Unlike other battery chemistries, LFP batteries break down into non-toxic compounds that do not harm the environment. This makes the disposal process safer.

Non-hazardous

As outlined in our installation manuals (Sections A.2.5 and A.2.6), PHI batteries are classified as non-hazardous and can be disposed of without damaging the ecosystem. They can also be returned to the earth, recombining easily with elements without producing harmful by-products.

Environmental Impact and PHI Battery Advantages

Our LFP chemistry and circuitry provide clear advantages over other Li-ion chemistries and other commercially available battery types. The minimal environmental impact during manufacturing, extended cycle life, and smaller end-of-life footprint underscores our commitment to sustainability. Our batteries are classified as non-toxic and non-hazardous by OSHA and WHMIS, making them the least polluting rechargeable batteries available today.