Generators Don't Produce the Same Amount of Power on Natural Gas vs. Propane

NGMaxTM Changes That

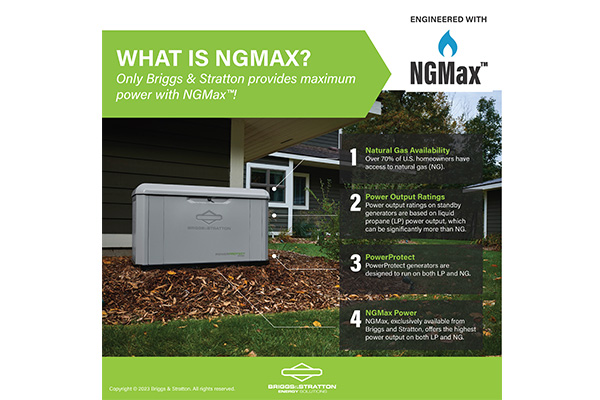

Selecting a fuel source for your generator might seem straightforward. However, most advertised standby generators' power ratings are measured using liquid propane fuel. This is surprising considering that 70% of U.S. homes are equipped with natural gas access, which you might expect to be the standard for fuel rating.

Let's explore some differences and common questions about the two fuels and how the Briggs & Stratton proprietary NGMax™ Technology corrects this power difference with technology that allows natural gas fuel to power at the same rate as propane power output ratings.

Why is propane used as the primary generator output rating?

Propane is used as a generator power rating because of its high energy density. In other words, per unit volume, propane packs more energy than natural gas. This leads to efficient fuel consumption, with generators requiring less propane to produce the same amount of electricity compared to natural gas.

Given its superior energy content, propane is often utilized as the benchmark for generator output ratings. It's not uncommon for manufacturers to highlight the maximum potential power output based on propane, as it showcases the generator in the best light - a marketing tactic.

For perspective, a generator's power output, when fueled by propane, might range between 7kW to 20kW — ample to electrify an average-sized home. In contrast, that same generator, when running on natural gas, might only yield up to 18kW.

NGMax™ Technology disrupts this disparity in output between propane and natural gas by being fuel agnostic when it comes to the output of natural gas versus propane. With this technology integrated, a natural gas-fueled generator can match the power output of its propane counterpart.

Traditional differences between propane and natural gas

When examining the energy content of propane and natural gas, the British Thermal Unit (BTU), a standard measure of heating efficiency, is commonly used. Specifically, one cubic foot of propane yields 2,516 BTUs, while the same volume of natural gas provides 1,030 BTUs.

In terms of energy density and consumption, propane requires less volume to produce a specified BTU output compared to natural gas. For a tangible comparison, consider a 100,000 BTU furnace using natural gas; it would consume approximately 97 cubic feet in an hour. In contrast, when fueled by propane, the consumption would be around 40 cubic feet for the same energy output. Or at least this was the case before Briggs & Stratton introduced the proprietary NGMax™ Technology, which creates a level playing field for natural gas.

How do Generators typically handle different fuels?

Different generators handle fuel differently. You can't always compare each model to another since some various components and improvements can change how fuel is handled in a particular model of generator. Standby generators can be adapted to a myriad of fuels, including gasoline, diesel, propane, and natural gas; each fuel type presents its own unique set of attributes.

Propane is more common in remote areas, and the fuel requirement varies based on several factors, like the generator's size, its runtime, and the load it's supporting. A 10-kilowatt generator typically consumes about 2.2 gallons of propane every hour.

Natural gas is a widely prevalent fuel source for 70% of people in the U.S. and showcases different consumption patterns. An average 10 kW generator running on natural gas is likely to burn approximately 1.5 gallons of gas per hour. If such a generator is operated for 8 hours daily, its consumption would round up to about 6 gallons.

Practical implications for end-users

Recognizing the need for reliable power sources during power outages and extreme weather events, Briggs & Stratton's NGMax™ technology addresses prolonged periods of operating a generator by maximizing natural gas power potential and improving fuel efficiency. This innovation allows users to tap into the more commonly available natural gas lines to fuel their generators. It offers a dependable solution during prolonged storms or natural disasters, particularly when propane delivery might be compromised.

Before choosing a generator and its corresponding fuel type, it's essential to familiarize yourself with the intrinsic differences between fuel options. Here's a checklist to help you make an informed decision.

Understand Output Ratings - Most standby generators display their power output ratings based on liquid propane, even though many homes are connected to a natural gas supply.

Propane's Edge in Energy Density - Propane offers more energy per unit volume compared to natural gas. This often results in a higher power output rating for generators using propane. If energy density is a priority, propane could be more favorable.

Availability of Fuel - While propane might be the preferred choice in remote areas due to its portability, natural gas pipelines are accessible to about 70% of U.S. homes. Consider the ease of sourcing and storing the fuel.

Environmental Considerations - Natural gas is primarily methane, which releases carbon dioxide when burned and can emit methane if there are leaks. Propane, while still a hydrocarbon, has a different combustion profile. Ensure you're aware of the environmental impact of your choice.

Cost Implications - Depending on the fuel source available to you, the price can vary based on supply, demand, and geographical location.

Integration of NGMax™ Technology - If you're considering a natural gas generator but are concerned about the traditional power output difference compared to propane, look for units with NGMax™ Technology. This ensures that the power output for natural gas matches that of propane.

Generator Size and Consumption Patterns - Different generator sizes have varying fuel consumption rates. A 10-kilowatt generator might use 2.2 gallons of propane per hour, while its natural gas counterpart could have different consumption patterns. Consider the operating costs and refueling frequency.

Maintenance and Longevity - Generators using different fuels might have distinct maintenance requirements. Research potential wear and tear and the longevity of units based on fuel type.

Air-Fuel Ratio - This is the volume of air required to combust a specific amount of fuel. For optimal efficiency and performance, ensure that your generator operates within the recommended air-fuel ratio range.

FAQs natural gas and propane for generators

What are the timing and plug gaps for propane and natural gas generators for best performance?

The optimal spark plug gap for natural gas is typically around 0.020-0.021 inches, regardless of weather conditions. In contrast, propane usually requires a larger spark gap of 0.024-0.026 inches for the best performance.

Is there a need for different settings when converting a factory NG set to run on propane?

Yes, many backup generators are initially designed to operate on a single fuel source, such as natural gas. However, they can be reconfigured to run on propane. This process usually requires adjustments to be made during installation or conversion. This conversion is no longer necessary with NGMax™ technology, as natural gas will now produce the same power output as propane and just needs the dealer to select which fuel source will be used and also select the correct controller profile.

How do different fuel compositions (flame rates, expansion curves) affect performance?

The quality and composition of the fuel significantly affect generator performance. Low-quality or impure fuels can disrupt the combustion process. Incomplete combustion due to impurities often results in reduced power output and can lead to increased wear and tear on the generator components.

What adjustments, if any, need to be made when changing fuel sources (for example, from propane to natural gas)?

Briggs & Stratton Generators are equipped to handle both fuel types, so there is no conversion kit necessary.

Is the incoming gas pressure relevant, and how does it affect the generator's performance?

Absolutely, maintaining the appropriate gas pressure is crucial. If the pressure is too high or too low, it can adversely affect the generator's performance, potentially damage appliances, and even pose safety risks.

The future with NGMax™

Briggs & Stratton's new PowerProtect™ generators featuring NGMax™ technology offer a promising glimpse of a future where homeowners can rely on the outpower rating when fueling with natural gas. Learn more about PowerProtect™ and the unique technology of NGMax™.

Ready to start protecting your home?

Our Whole-House Generator Sizing Calculator allows you to select what you want to power in your home and directs you to the appropriate-sized generator system.